Manufacturing method of rigid cathode wire elastic connection plate

【 Technical field 】

This utility model relates to aElectrostatic precipitatorEspecially involving a type of electricitydust collectorUse rigid cathode wire elastic connection plate.

[Background Technology]

At present, there are many types of cathode wires used in electrostatic precipitators, such as tubular barbed wire, square tube needle punched wire, tubular multi needle wire, spiral wire, etc. The mechanical strength of the rigid cathode wire is high and it is not easy to shake in an electric field. However, the installation method between the rigid cathode wire and the cathode frame is mostly bolted and fixed. During on-site installation and construction, bolts and nuts are generally spot welded, which can easily cause bolts and nuts to fall off. Bolts and nuts falling into the ash hopper may cause malfunctions in the ash discharge valve and other components of the ash conveying system at the bottom of the hopper, affecting the normal operation of the electrostatic precipitator. The strength of rigid cathode wires is generally high, and their shape is also relatively large, resulting in higher costs. They lack elasticity, and in order to prevent thermal expansion from damaging the cathode wire, the connection between one end and the frame is made in a loose state by using a waist shaped hole without being compressed. If the external dimensions of the cathode wire are reduced, the rigidity will deteriorate and there may be significant shaking.

At present, the connection plate of rigid cathode wires is generally welded to the cathode frame by ordinary electric welding. Due to the large number of cathode wires, not only is the workload heavy, but also the welding fumes pollute the workshop environment, which is not conducive to the health of workers.

At present, the environmental protection industry urgently needs rigid cathode wire installation accessories and installation methods that can increase the elasticity of cathode wires, have high reliability, simple production processes, and good environmental friendliness.

[Invention Content]

The technical problem to be solved by this utility model is to provide a rigid cathode wire elastic connection plate for electrostatic precipitators that can increase the elasticity of the rigid cathode wire, has no welding on site, and has a small installation workload.

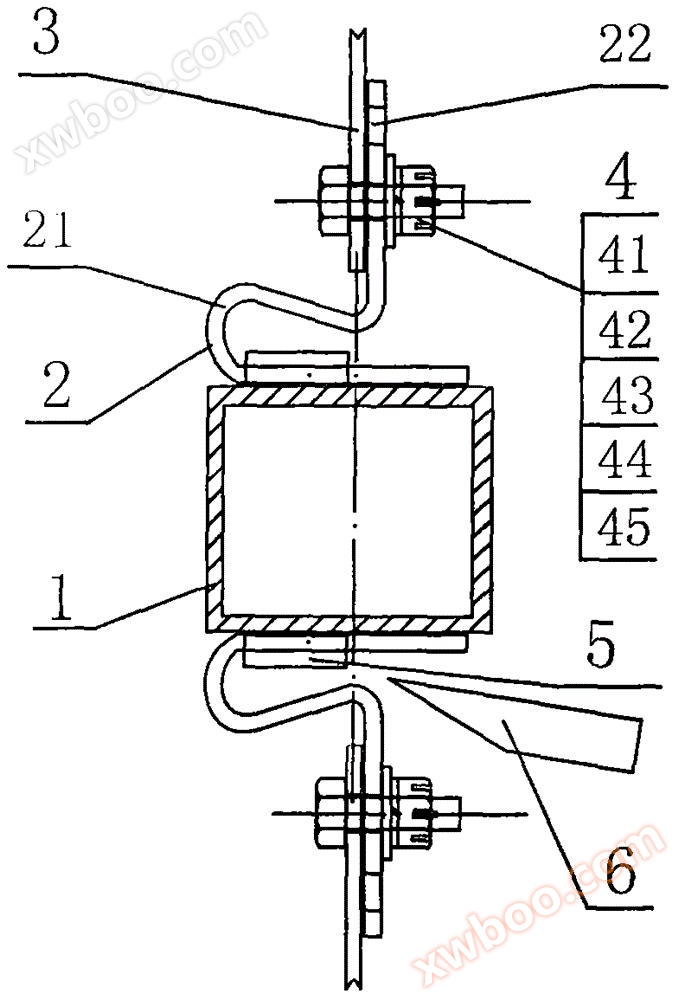

This utility model relates to a rigid cathode wire elastic connection plate, comprising a cathode frame, an elastic connection plate, a rigid cathode wire, fastening bolts, a spot welding pressure plate, and an inclined handle for installation. The elastic connection plate is made of elastic steel plate and has an elastic arc. It is fixed to the cathode frame by resistance welding. The spot welding pressure plate presses against the elastic connection plate and spot welds on the cathode frame for reinforcement. The fastening bolts adopt a structure of perforated bolts, slotted nuts, and right angle galvanized steel wire pins to prevent loosening. During installation, only bolts and nuts need to be installed on site, and after installation, the rigid cathode wire can also be made elastic.

The elastic connecting plate is formed by stamping elastic steel plates and is equipped with elastic arcs.

The elastic connection plate is punched with installation holes and spare holes, which can obtain different installation hole distances. When installing the rigid cathode wire, the appropriate installation hole should be selected to make the elasticity more suitable.

The elastic connecting plate and the cathode frame are fixed by resistance welding, and then a spot welding pressure plate is placed on one side of the elastic arc and fixed by resistance welding.

Right angle galvanized steel wire is made by bending one end of the galvanized steel wire into a right angle.

When installing the rigid cathode wire, one end of the rigid cathode wire is fixed to the elastic connecting plate with fastening bolts. The fastening bolts are a combination of perforated bolts, flat washers, spring washers, and slotted nuts. After tightening the nuts, a right angle galvanized steel wire pin is inserted into the small hole of the perforated bolt along the groove and bent and compressed.

When installing the other end of the rigid cathode wire, the inclined handle for installation is inserted into the opening of the elastic arc to increase the opening of the elastic connecting plate and cause deformation. Then, the perforated bolt, flat washer, spring washer, and slotted nut are tightened, and a right angle galvanized steel wire pin is inserted into the small hole of the perforated bolt along the groove and bent and compressed. The inclined handle for installation is pulled out, and the elastic arc acts as a tension to make the rigid cathode wire elastic, improve the vibration cleaning effect, and reduce the external dimensions of the rigid cathode wire, saving production costs.

Compared with the existing technology, this utility model has the following obvious advantages and positive effects:

I. The elastic arc of the elastic connecting plate deforms and generates elastic force, making the rigid cathode wire also elastic, improving the vibration cleaning effect, and reducing the external dimensions of the rigid cathode wire, saving costs.

2. Fixed with perforated bolts and right angle galvanized steel wire pins, eliminating on-site welding, making it easy and reliable. The bolts and nuts will not loosen or fall off, which is beneficial for the long-term stable operation of the electrostatic precipitator.

[Attached Figure Explanation]